General Information / Purpose

The City of Suffolk has entered into a Special Order by Consent (SOBC) with the Virginia Department of Environmental Quality, the Hampton Roads Sanitation District, as well as 12 other Hampton Roads localities. The purpose of the SOBC is to reduce the occurrence of Sanitary Sewer Overflows (SSOs) in the sanitary collection system. As part of the SOBC, the City has implemented a program to identify and mitigate SSOs and to develop a long-term capital improvement plan that rehabilitates the system for the future prevention of SSOs.

Currently, the Department of Public Utilities operates and maintains the sanitary sewer system for the City of Suffolk. The sanitary sewer system is comprised of over 150 sewer pump stations, 375 miles of gravity sewer lines, over 90 miles of sewer force mains, and conveys wastewater to the sewage treatment plants operated by the Hampton Roads Sanitation District.

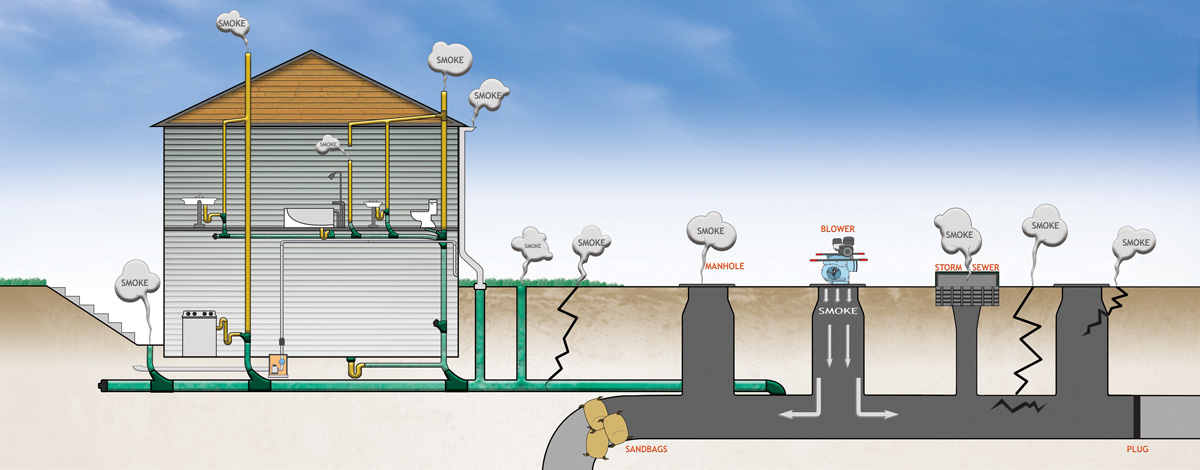

Jacobs, a global leader in full-service engineering, construction, and operations is currently working with the City of Suffolk to implement a condition assessment program of the sanitary sewer system. An important goal of the condition assessment program is to address deficiencies which contribute to SSOs. A smoke testing program is being conducted as part of the condition assessment. Smoke testing is an effective way to locate and identify problems and defects that can contribute to SSOs and decrease the existing capacity and efficiency of the collection system infrastructure.

Public door hanger notification for smoke testing of sanitary sewer lines in the work area will be distributed to residents and commercial areas prior to field investigations. The door hanger will describe the upcoming smoke testing efforts and what should be done in advance to minimize smoke from entering buildings. Residents do not need to be home during the testing. Contact information will be provided on the door hanger in the event smoke does enter a building.

Neighborhoods to be tested will be published weekly in the Schedule/Map section.

Additionally, anticipated work areas for the upcoming work week will be published in the Sunday issue of the Suffolk News-Herald.

During testing, crews will seal off segments of the sanitary sewer system and push smoke into the gravity sewer pipes with smoke blowers. Materials used to generate the smoke are non-toxic, harmless, virtually odorless, and do not create a fire hazard.

Should smoke enter your home or business, the room should be promptly ventilated through an open window or door.